Designing for 3D printing

Let's find out together what are the limits and possibilities given by designing objects for self-production with 3D printing

What does it mean to design for 3D printing?

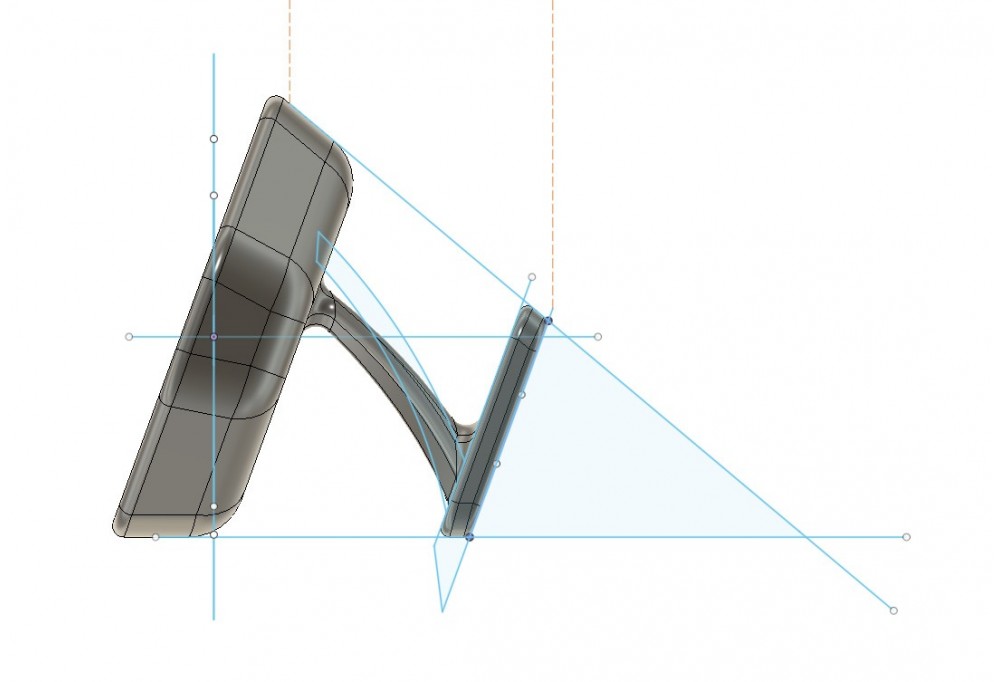

Today an industrial design project arises from the awareness of the potential and limits of the materials that will be used and from the knowledge of production methods.

From this point of view, designing PLA objects that will be made in FDM printing is no different from what should be the normal practice of good design.

The real difference is that to all the factors to be taken into consideration we must add a production process that will not be controlled and controllable. To explain this better, this means that designing for 3D printing is not making an object that then requires special equipment or skills to be produced. Good design for consumer-grade FDM printing is one that works perfectly with a mid-range, mid-skilled printer.

What are the major limitations?

Augusto Morello, great promoter of Italian design in the world, affirmed that design is that thing that is between zero and infinite constraint.

The design constraints are therefore not limits but a set of conditions to be respected. Good design is the one that manages to respond in the best, original, linear, and effective way to these conditions.

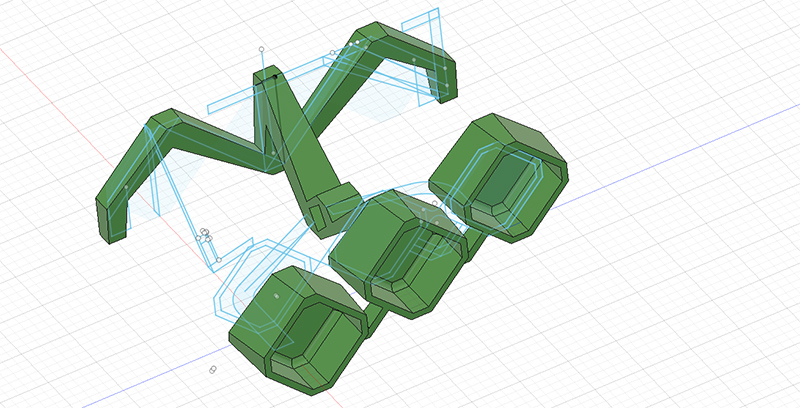

We have consciously chosen to design using PLA as a material and as a production reference target a consumer-grade FDM printer with standard dimensions and performance (eg print size 20x20x25 cm). In addition to this, at the moment our line consists of objects that do not require post production and that can be assembled without the need for glue, screws or other.

And with pride we can say that at the moment no other company offers a catalog of objects with these characteristics, variety and quality

What are the benefits ?

From the designer's point of view, this method of selling directly to the final consumer is a recovery of origins. Too often we design by listening to the indications coming from the marketing offices and market surveys. We want to gain the freedom to return to a vital and creative exchange, to dialogue and listen to those who use and appreciate our objects.

The user has the advantage of being able to purchase the possibility of producing design pieces at very low entry prices. Buy a "personal use license" and can create and own as many copies of that item as he wants. For example, he could buy a photo frame and then produce ten pieces of different colors and maybe even sizes. This is done without having to spend more money than the original purchase.

We then have an advantage that is fundamental for us, indeed it is the main engine that prompted us to found Tulofai: eco-sustainability. We propose a model in which the objects are produced in the place of their use and in the strictly necessary quantity. Using a frendly eco material like PLA. Thus reducing the environmental impact deriving from production, storage and transport of goods.